|

|

|

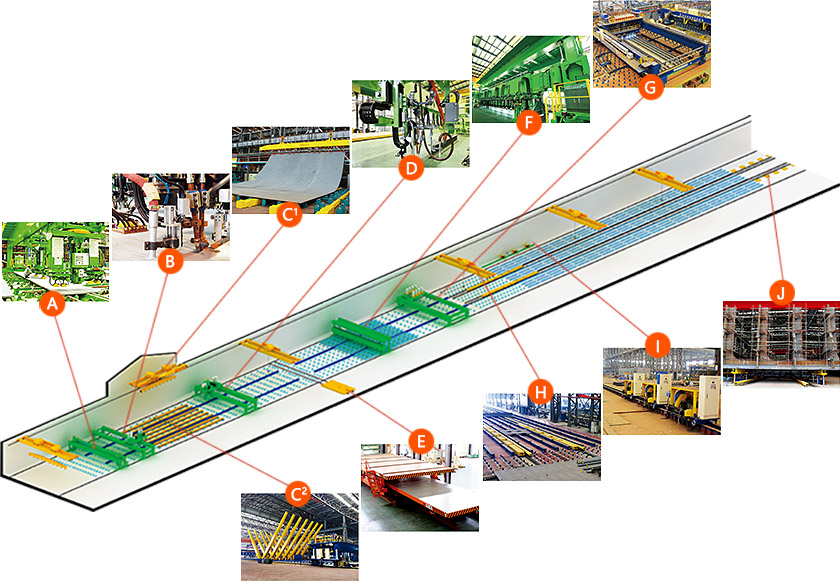

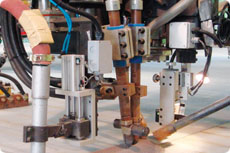

This stage is used to adjust alignment and join main plates of ship flat blocks which are cut CNC cutting machine. It controls alignment, gap and step between the plates to join them by tack welding. |

|

| Component | Gantry Girder / Carriage / Bogie Wheel + Rack Rail / Hydraulic Press Slewing Device / Magnet Device / Welding Torch + Feeder |

| Operation Axle | Travelling & Traversing & Up-Down |

| Driving Method | Electric Motor + Reducer + Bogie Wheel |

| Control Method | PLC Control |

| Power Source | AC 500A Manual Type |

| Welding Method | Tack Welding + Auto Laser Sensor |

| Safety Device | Anti-Collision Device |

|

|

|

This stage is used to weld main plates which come from the previous stage(Plate Joining) by Submerged Arc Welding (SAW). Multi-pole welding enables to increase productivity. It allows to weld up to 25mm thickness by tworun technique as square butt joint. |

|

| Component | Gantry Girder / Carriage / Bogie Wheel + Rack Rail 2Head Slewing Device / Welding Torch + Feeder |

| Operation Axle | Travelling & Up-Down |

| Driving Method | Electric Motor + Reducer + Bogie Wheel |

| Control Method | PLC Control |

| Power Source | AC 1600A / DC 1250A Inverter Type |

| Welding Method | Submerged Welding Auto Laser Sensor |

| Welding Technique | Twin Tandem Submerged Auto Welding |

| Safety Device | Anti-Collision Device |

|

C1. Turn over stage - crane turn over system |

|

| Component | Crane Lifting Beam Clamp / Stopper |

| Driving Method | Over Head Crane |

| Control Method | - |

| Operation Angle | - |

| Capacity Size | Stopper 1m x 0.5m |

| Weight | ~ 130 Ton (abt) |

| Dead Load | 15 Ton |

C2. Turn over stage - flip turn over system |

|

| Component | Multiple Lifting Beam |

| Driving Method | Hydraulic System |

| Control Method | Synchronization PLC Auto / Manual |

| Operation Angle | 0° ~ 100° / each side |

| Capacity Size | Standard 20m x 20m |

| Weight | ~ 130 Ton (abt) |

| Dead Load | - |

|

|

|

This equipment is used to fit up of longitudinal stiffeners by tack welding on the main plate which comes from the previous stage (Butt welding stage). |

|

| Component | Gantry Girder / Carriage / Bogie Wheel + Rack Rail Magnetic Press Device / Welding Torch + Feeder |

| Operation Axle | Travelling & Up-Down |

| Driving Method | Electric Motor + Reducer + Bogie Wheel |

| Control Method | PLC Control |

| Power Source | AC 500A Manual Type |

| Welding Method | Tack Welding (FCAW) |

| Safety Device | Anti-Collision Device |

|

|

|

This equipment is used to weld longitudinal stiffeners fitted on the main plate. Mostly welding will be done by FCAW process and both side welding can be done simultaneously. Number of welding pole depends on the customer's requirements up to 40 poles. |

|

| Component | Gantry Girder / Carriage / Bogie Wheel + Rack Rail Pneumatic Device / Welding Torch + Feeder |

| Operation Axle | Travelling & Traversing & Up-Down |

| Driving Method | Electric Motor + Reducer + Bogie Wheel |

| Control Method | PLC Control / Noise Auto Control |

| Power Source | AC 600A Inverter Type |

| Welding Method | Auto Welding |

| Welding Technique | Twin Tandem FCAW |

| Safety Device | Anti-Collision Device |

|

|

|

It transfer flat blocks from one stage to next stage according to production work flow. It can lift maximum 400 tons single block by combining two (2) rows of transfer car. This equipment shall in installed under the fixed working table, controlled by remote controller. Cable pendent also can be used for emergency case. |

|

Plate Joining Equipment

Plate Joining Equipment Butt welding equipment - front side welding

Butt welding equipment - front side welding Turn Over Stage

Turn Over Stage Butt welding equipment - back side welding

Butt welding equipment - back side welding

Longitudinal transfer car

Longitudinal transfer car

Longitudinal fit-up equipment

Longitudinal fit-up equipment Multi pole longitudinal auto welding Equipment

Multi pole longitudinal auto welding Equipment Block transfer car

Block transfer car Pulling winch

Pulling winch

Block lifting system

Block lifting system