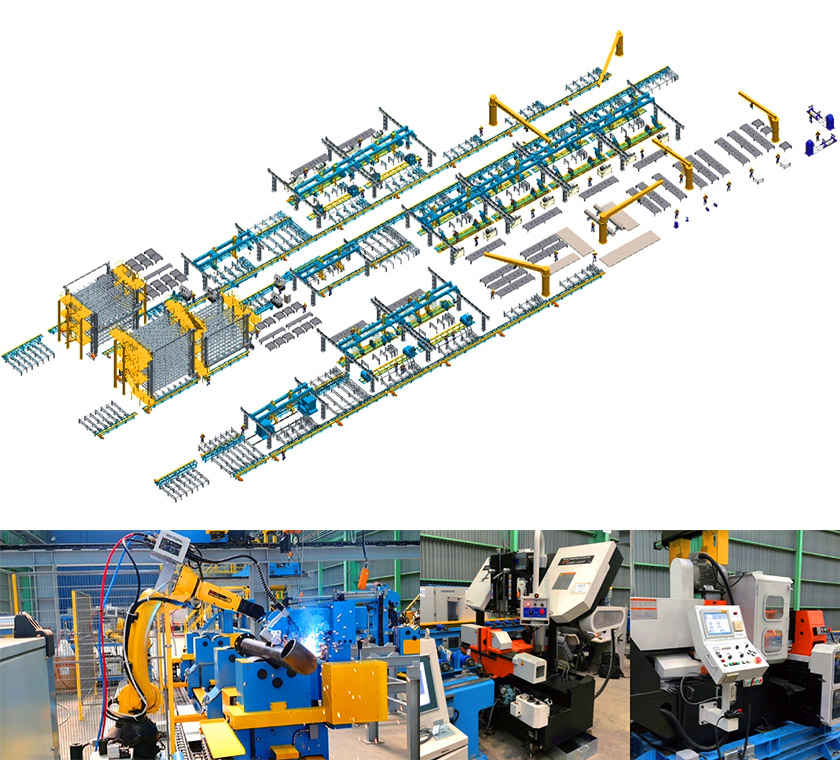

This system is specially developed for 3D pipe spool production in automatic mode. Through MES control, entire production process can be planned and managed in high efficient ways from the supply raw materials to cutting, bevelling, welding and bending. This automatic solution can minimize number of manpower in workshop.

| Pipe rack | It is used for pipe (Φ48.6~Φ355mm) to store and supply into production line for various pipe according to plan |

| Band saw | Cutting dia. (Φ48.6~Φ610mm) / Blade speed. Max 90mm/min Center clamping device, Laser marking system, Auto cutting system |

| Facing machine | Facing dia. (Φ48.6~Φ610mm) / Multi shape beveling(I, V, J) / Auto pipe feeding system Center clamping device |

| Welding fit up machine | Auto pipe feeding system / Multi jig for flange and elbow / Foot pedal |

| Robot welding machine | Rail shifting system of turning roller / Turning roller rail shifting system Indivisual movement / Indivisual robot control system / Welding data management |

| CNC pipe coaster | Plasma and Oxygen cutting / Cutting according to the shape input Cutting program using auto cad |

| CNC pipe bending machine | Bending program using auto cad / Cold bending max dia. (~ Φ219mm) / 2axis,1stack Auto lubrication system / Touch screen control |

| Welding chuck & Turning roller | Clamping for various sizes of pipe / Welding foot pedal Robot and welding speed synchronization |

Pipe shop capabilities

| Material | Carbon, Stainless, Non-ferrous |

| Diameter | ½”(21.3mm) through 48”(1,219mm) diameter |

| Working area | 15,120㎡ |

| Lay out configuration | Material warehouse stage, Hydro testing of the pipeline, Pipe spool fabrication stage (Auto welding, 2D, 3D welding stage) |

| Customized production software | M.E.S(Developed by SCADA) |